We participated at the Second Contract logistics “Gino Marchet” workshop of the Politecnico di Milano. As always, the workshop is a great opportunity to understand the main trends that shape the evolution of logistics 4.0.

One of the themes of the 2022 research is innovation in the customer-supplier relationship, or the relationship between those who use transport services and those who offer them; among the key message that the Politecnico launched to the workshop participants, first is the increase in awareness that transport has a “finite capacity” (for all the reasons that in recent years have become evident even to those who do not closely follow the world of logistics), then the need to further develop a “tactical” level of transport planning, which aligns the “demand” for transport with the supply, or rather the transport capacity (in analogy to what happens for example for the S&OP).

What emerges today as a necessity is actually a trend that has been underway for several years: for customers who had expressed the need to “anticipate” transport capacity problems, Optit provided optimization solutions integrated with TMS / WMS that go beyond the “classic” operational planning systems (which support, for example, the creation of the next day’s travel plan) and support a real “capacity planning”.

These are solutions that integrate advanced algorithmic models which, based on the order book of the following days (usually on a 1-2 week horizon) and capacity constraints (e.g. number of vehicles available on certain routes), are able to provide an outlook of how the availability of means of transport will be saturated (or not), allowing for example to release the vehicles in case of probable inactivity (and therefore avoid penalties) or to request additional vehicles within the contractual limits (days in advance for the request, etc.). Naturally these systems are able to manage all the operational constraints required by the business: mandatory (or not) delivery days, capacity of vehicles differentiated by type, compatibility between goods and type of vehicle, optimal saturation of the vehicle, etc.

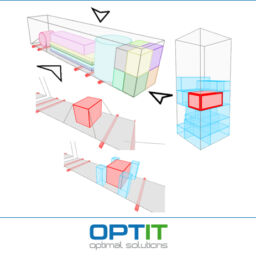

For an optimal use of the transport capacity, it is also possible to use load optimization models (load building problems) to support other business functions to make decisions much further upstream than transport planning. A (real) case is the use of these algorithms to “suggest” to the Sales how to “complete” a customer order to build a complete load (ie that saturates an entire vehicle, a container, etc.).

But that is a good theme for another workshop…